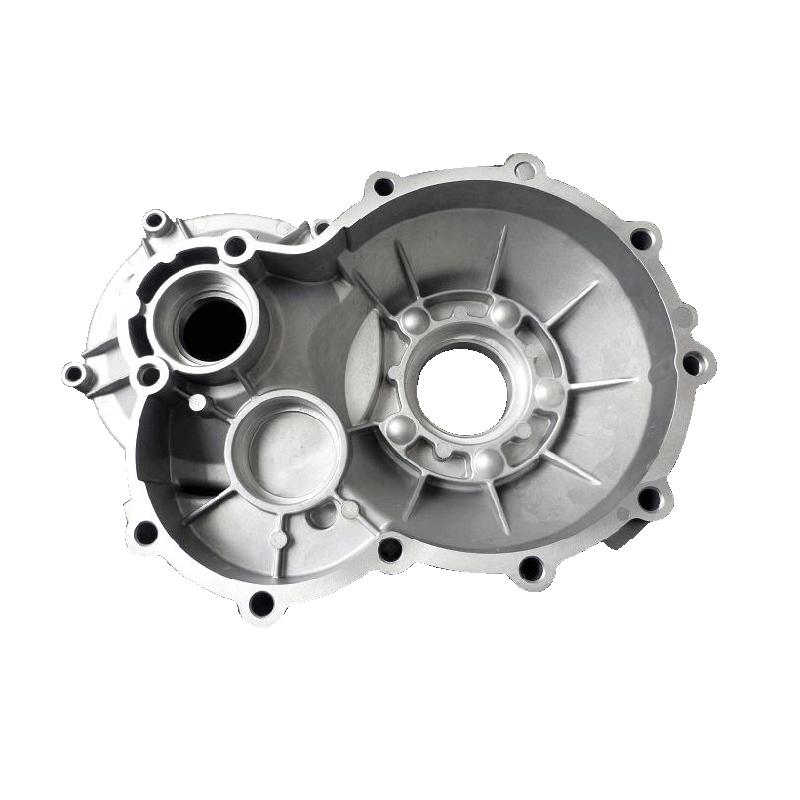

Daidaito da inganci suna da mahimmanci don aiki mai kyau na tsarin injina daban-daban. Wani muhimmin sashi a cikin tsarin watsawa shinemurfin akwatin kayan wasan kwaikwayo na aluminumA cikin wannan shafin yanar gizo, za mu binciki tsarin da ya fi rikitarwa na samar da sassan simintin aluminum masu inganci, tun daga farko har zuwa ƙarshe.

Gilashin Mutu Mai Matsi Mai Girma:

Don fara aikin, ana amfani da simintin ƙarfe mai ƙarfi don siffanta ƙarfen aluminum zuwa murfin akwatin gear da ake so. Wannan hanyar ta ƙunshi allurar aluminum mai narkewa a cikin ƙarfe a ƙarƙashin matsin lamba mai yawa, don tabbatar da kwafi daidai na ƙirar mold. Sakamakon shine siminti mai ƙarfi da daidaito wanda ke nuna kyawawan halayen injiniya.

Gyara da Rage Girman:

Bayan an gama yin amfani da kayan, ana yin gyaran murfin akwatin gear da kuma cire kayan. Gyaran ya ƙunshi cire kayan da suka wuce gona da iri a gefunan simintin don cimma siffar da girman da ake so. Gyaran, a gefe guda, ya ƙunshi kawar da duk wani gefuna ko burrs masu kauri da suka samo asali yayin aikin simintin. Waɗannan matakai biyu suna haifar da murfin akwatin gear mai tsabta da aka shirya don ƙarin gyare-gyare.

Harbi Mai Busawa:

Busar da harsashi muhimmin mataki ne a cikin tsarin ƙera shi, domin yana kawar da duk wani datti da ya rage daga saman murfin akwatin gear. Wannan hanyar ta ƙunshi tura ƙananan ƙwayoyin ƙarfe cikin sauri zuwa saman, ta yadda za a cire duk wani datti, sikelin, ko iskar shaka da zai iya shafar bayyanar ƙarshe da aikin ɓangaren. Busar da harsashi yana tabbatar da santsi da tsabta, a shirye don mataki na gaba.

Goge saman:

Domin inganta kyawun murfin akwatin gear da juriya, ana amfani da goge saman. Wannan tsari ya ƙunshi niƙa da kuma goge saman ta amfani da kayan gogewa da mahaɗan. Manufar ita ce a cimma kamannin madubi, inganta kyawun gani da juriyar tsatsa na ɓangaren. Goge saman yana ba murfin akwatin gear kamanni na ƙwararru kuma mara aibi.

Injin CNC da Taɓawa:

Domin tabbatar da cewa murfin akwatin gear ya dace da tsarin watsawa ba tare da wata matsala ba, ana yin injin CNC da kuma dannawa. Injin CNC ya ƙunshi cire duk wani abu da ya wuce gona da iri da kuma gyara mahimman ma'auni don cimma takamaiman buƙatun da ake so. Dannawa ya ƙunshi ƙirƙirar zare a cikin simintin da ke ba da damar shigarwa da haɗi mai sauƙi tare da wasu abubuwan haɗin. Waɗannan matakan suna tabbatar da dacewa da aikin murfin akwatin gear.

Samar dababban daidaitaccen sassan simintin aluminum mututafiya ce mai kyau wacce ta haɗu da hanyoyin kera kayayyaki daban-daban. Tun daga farko har zuwa matakai daban-daban na kammalawa, kamar yankewa, cire kayan aiki, fashewar harbi, goge saman, injin CNC, da kuma taɓawa, kowane mataki yana ba da gudummawa ga ƙirƙirar murfin akwatin gear mai inganci don tsarin watsawa. A ƙarshe, waɗannan sassan suna taka muhimmiyar rawa wajen tabbatar da ingantaccen aiki na tsarin injina, suna misalta mahimmancin injiniyan daidaito a masana'antu na zamani.

Lokacin Saƙo: Agusta-14-2023