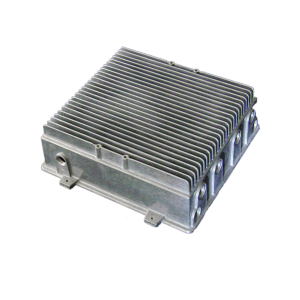

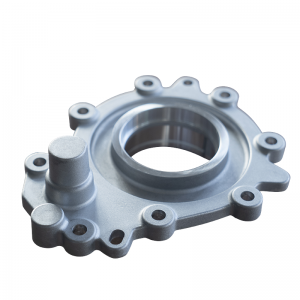

Murfin sadarwa/gidaje na simintin aluminum mai matsin lamba

Cikakkun Bayanan Samfura

| Sarrafawa | Simintin aluminum / simintin aluminum / simintin aluminum |

| Gyaran gashi | |

| Buɗewa | |

| Busasshen dutsen ado | |

| Goge saman | |

| Injin CNC, dannawa, juyawa | |

| Rage mai | |

| Rufin foda da launin baƙi | |

| Duba girman | |

| Injina | Injin simintin Die daga 450 ~ 1650tons |

| Injinan CNC guda 60, gami da alamar Brother da LGMazak | |

| Injinan hakowa 6 sets | |

| Injinan tapping set 5 | |

| Layin rage mai | |

| Layin shigarwa ta atomatik | |

| Matsewar iska saiti 8 | |

| Layin shafa foda | |

| Spectrometer (binciken kayan abu) | |

| Injin aunawa mai daidaitawa (CMM) | |

| Injin X-RAY don gwada ramin iska ko porosity | |

| Mai gwajin tauri | |

| altimita | |

| Gwajin fesa gishiri | |

| Aikace-aikace | Tushen simintin aluminum, akwatunan motoci, akwatunan batirin motocin lantarki, murfin aluminum, gidajen gearbox da sauransu. |

| Tsarin fayil ɗin da aka yi amfani da shi | Pro / E, Auto CAD, UG, m aiki |

| Lokacin jagora | Kwanaki 35-60 don mold, kwanaki 15-30 don samarwa |

| Babban kasuwar fitarwa | Yammacin Turai, Gabashin Turai, Amurka |

| Amfanin kamfani | 1) ISO 9001, IATF16949, ISO14000 |

| 2) Bita na simintin siminti da fenti na mutu mallakar su | |

| 3) Kayan aiki masu inganci da ƙungiyar R&D mai kyau | |

| 4) Tsarin masana'antu mai ƙwarewa sosai | |

| 5) Nau'ikan samfuran ODM da OEM iri-iri | |

| 6) Tsarin Kula da Inganci Mai Tsauri |

Tsarin Samar da Fitar da Die:

1. Tambaya - Duba duk buƙatun a bayyane suke -->

2. Ambato bisa ga zane na 2D da 3D-->

3. An Saki Odar Siyayya-->

4. An tabbatar da matsalolin ƙira da samarwa na mold--->

5. Yin mold-->

6. Sashen Samfura-->

7. An Amince da Samfurin-->

8. Samar da kayayyaki da yawa--->

9. Isarwa da sassa--->

Bayanin DFM na Casting na ALUMINUM DIE

Tsarin Masana'antu (DFM) kalma ce da ake amfani da ita a fannin injiniyanci. Tana nufin tsarin inganta samarwa zuwa ga

sanya shi ya zama mai sauƙi kuma mai araha gwargwadon iyawa. DFM ta fi mai da hankali kan hanyoyin ƙera da hanyoyin da ake amfani da su.

Ɗaya daga cikin manyan fa'idodin DFM shine yana ba da damar gano matsalolin da ke tattare da hanyar samarwa da kuma magance su da wuri

a matakin ƙira. A wannan matakin, matsaloli suna da rahusa a warware su fiye da lokacin da aka gano su a lokacin ko bayan an gano su.

Gudanar da samarwa. Amfani da dabarun DFM yana ba da damar rage farashin masana'antu yayin da ake kula da kaya ko

mafi kyawun ma'aunin inganci.

Domin inganta tsarin samar da simintin aluminum, ya kamata a yi niyya ga waɗannan manufofi:

1. Yi amfani da mafi ƙarancin adadin kayan simintin da za a iya samu,

2. Tabbatar cewa ɓangaren ko samfurin zai fito cikin sauƙi daga cikin injin,

3. Rage lokacin ƙarfafawa don yin siminti,

4. Rage yawan ayyukan sakandare gwargwadon iyawa,

5. Tabbatar cewa samfurin ƙarshe zai yi aiki kamar yadda ake buƙata.

Ganin masana'antarmu

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com