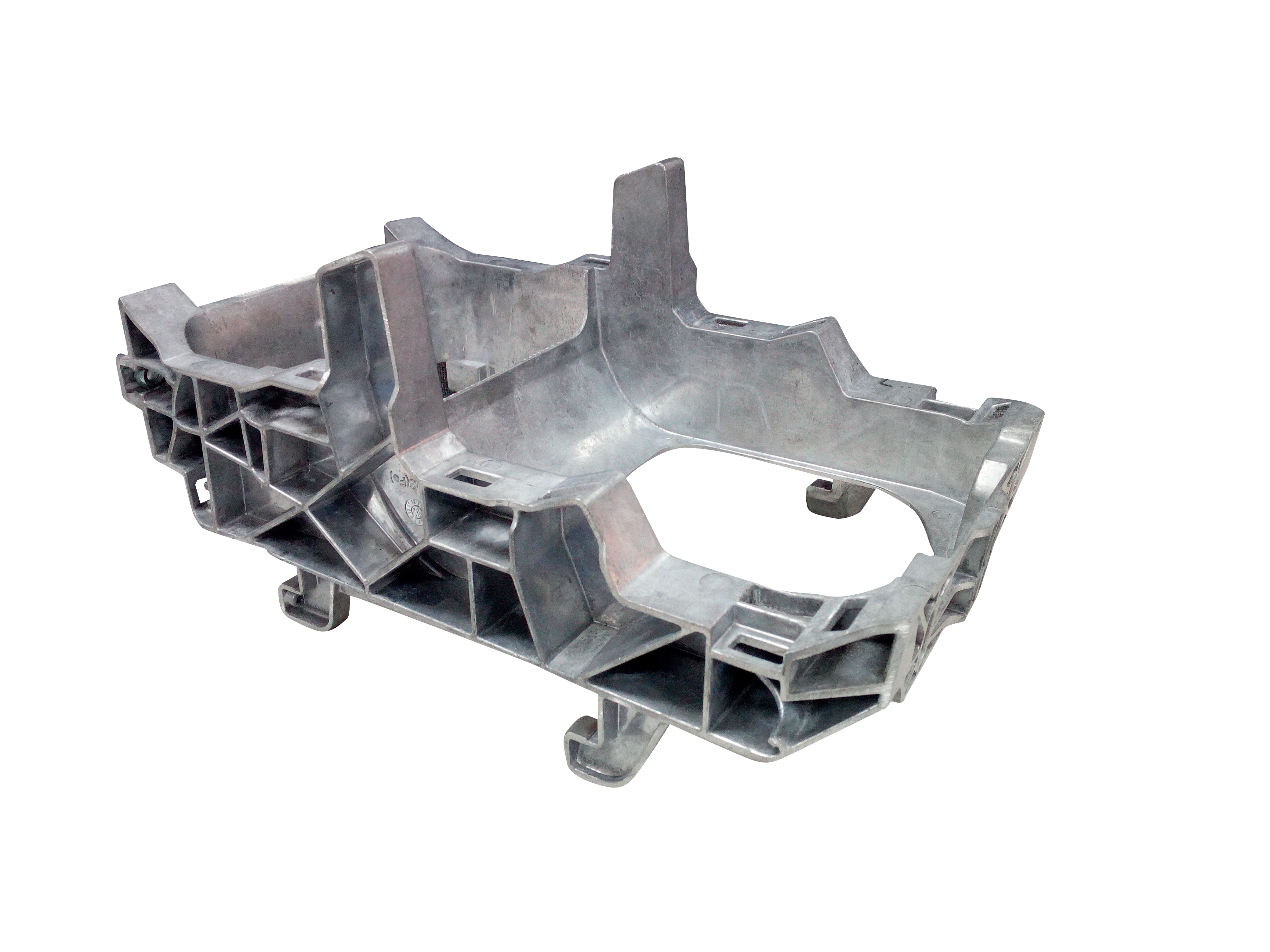

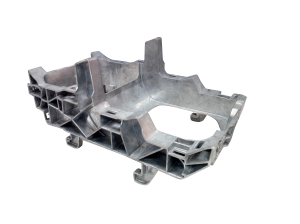

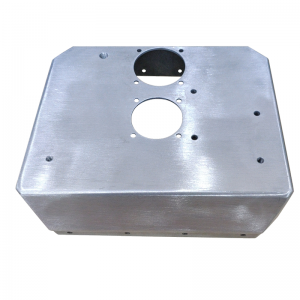

Tushen simintin ƙarfe mai ƙarfi na aluminum don sassan mota

Cikakkun Bayanan Samfura

| Sarrafawa | Injin sanyaya iska mai ƙarfi ta hanyar injin sanyaya iska Gyaran gashi Buɗewa Harbin bindiga Goge saman Injin CNC, tapping, juyawa Rage mai Dubawa ga duk girma musamman girman maɓalli |

| Injina | Injin simintin Die daga 250 ~ 1650tonsInjinan CNC guda 130, gami da alamar Brother da LGMazakInjinan hakowa 6 sets Injinan tapping set 5 Layin rage man shafawa ta atomatik Layin shigarwa ta atomatik Matsewar iska saiti 8 Layin shafa foda Spectrometer (binciken kayan abu) Injin aunawa mai daidaitawa (CMM) Injin X-RAY don gwada ramin iska ko porosity Mai gwajin tauri Altimita Gwajin fesa gishiri |

| Aikace-aikace | Gidajen aluminum, akwatunan motoci, akwatunan batirin motocin lantarki, murfin aluminum, gidajen gearbox da sauransu. |

| Tsarin fayil ɗin da aka yi amfani da shi | Pro / E, Auto CAD, UG, m aiki |

| Lokacin jagora | Kwanaki 35-60 don mold, kwanaki 15-30 don samarwa |

| Babban kasuwar fitarwa | Yammacin Turai, Gabashin Turai |

| Amfanin kamfani | 1) ISO 9001, IATF16949, ISO140002) Mallakar kayan aikin siminti da fenti na foda3) Kayan aiki masu inganci da ƙungiyar R&D mai kyau4) Ƙwararrun tsarin kera kayayyaki5) Iri-iri iri-iri na samfuran ODM&OEM6) Tsarin Kulawa Mai Inganci |

Tsarin Samar da Simintin Die

1. Tambaya - Duba duk buƙatun a bayyane suke -->

2. Ambato bisa ga zane na 2D da 3D-->

3. An Saki Odar Siyayya-->

4. An tabbatar da matsalolin ƙira da samarwa na mold--->

5. Yin mold-->

6. Sashen Samfura-->

7. An Amince da Samfurin-->

8. Samar da kayayyaki da yawa--->

9. Isarwa da sassa

Tambayoyin da ake yawan yi game da simintin Die

1. Menene Bambancin Tsakanin Simintin Aluminum Die da Simintin Yashi?

Babban bambanci tsakanin simintin da aka yi da simintin yashi shine kayan da ake yin simintin. Simintin aluminum yana amfani da simintin da aka yi da ƙarfen aluminum. A gefe guda kuma, simintin yashi yana amfani da simintin da aka yi da yashi.

Simintin yashi yana da ikon yin aiki tare da ƙira masu rikitarwa. A gefe guda kuma, simintin yashi yana ba da daidaito da sauri mafi girma.

Wani muhimmin bambanci shi ne, yin yashi yana samar da kauri bango yayin da yin yashi na iya samar da kauri bango. Saboda haka, yin yashi ba shi da kyau ga ƙananan sassa.

Saurin samarwa wani muhimmin bambanci ne tsakanin waɗannan dabarun guda biyu. Kayan aikin simintin mutu aiki ne mai sarkakiya kuma yana buƙatar lokaci mai tsawo. A gefe guda kuma, kayan aikin simintin yashi tsari ne mai sauƙi kuma yana buƙatar ƙarancin lokaci fiye da simintin mutu.

Simintin ƙarfe ya dace da manyan kayayyaki kamar idan kuna buƙatar dubban sassa. Amma simintin yashi ya dace da ƙananan kayayyaki kamar raka'a 100-150.

2. Yaya Tsada Gilashin Aluminum Yake?

Simintin aluminum yana ɗaya daga cikin hanyoyin simintin ƙarfe mafi araha. Duk da cewa kayan aikin simintin die yana buƙatar ƙarin lokaci, za ku iya ƙirƙirar dubban raka'a tare da mold ɗaya. Da yawan abin da kuka samar, ƙarancin farashin na'urar ku zai zama. Aluminum ya fi rahusa fiye da bakin ƙarfe kuma ya ɗan fi tsada fiye da ƙarfen carbon.

3. Yaya saurin tsarin simintin ya kasance?

Simintin Die tsarin siminti ne na atomatik. Yana ɗaukar lokaci kafin a ƙirƙiri mold. Amma mold ɗin zai iya ƙarfafa ƙarfen aluminum da sauri. Kuma tunda tsari ne na atomatik, injin zai iya ƙera na'urori da yawa ba tare da ɓata lokaci ba. Saboda haka, simintin die tsari ne mai sauri musamman lokacin da kake ƙera adadi mai yawa na sassa.

Ganin masana'antarmu

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com