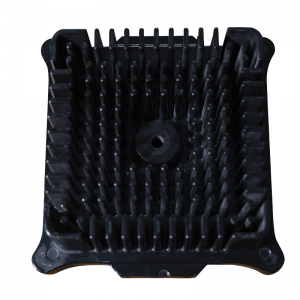

Heatsink ɗin aluminum die cast tare da fins ɗin extruded

Simintin siminti tsari ne mai inganci sosai wanda zai iya samar da sassa masu siffofi masu rikitarwa. Tare da simintin simintin simintin simintin zafi, ana iya haɗa fin ɗin simintin zafi cikin firam, gida ko kabad, don haka ana iya canja wurin zafi kai tsaye daga tushe zuwa muhalli ba tare da ƙarin juriya ba. Idan aka yi amfani da shi zuwa ga cikakken ƙarfinsa, simintin ...

Amfanin Die Cast Heatsink

Ya dace da samfuran siffofi daban-daban.

Rage farashin sarrafawa.

Binciken kwararar mold na ƙwararru don rage lokacin zagayowar haɓaka samfura da inganta yawan amfanin samfura.

Injin CMM mai cikakken atomatik don tabbatar da cewa girman samfurin ya cika ƙa'idodin.

Kayan aikin duba X-ray suna tabbatar da babu lahani a cikin samfurin da aka yi amfani da shi.

Rufin foda da sarkar samar da kayayyaki ta Cataphoresis suna tabbatar da ingancin ingantaccen maganin saman samfurin.

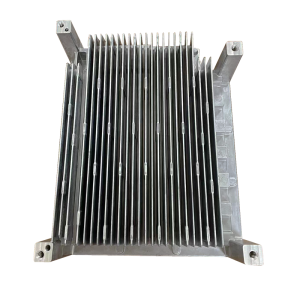

Babban tsari na extrusion da aka yi da fin+Mutu simintin

Fikafikan da aka fitar ta hanyar kayan aikin extrusion.

Jikin aluminum mai siffar mutu.

Injin CNC/yanka yanke/yanka giciye zuwa siffar da ake buƙata.

Bututun zafi na haɗawa/bututun jan ƙarfe/bututun bakin ƙarfe/bututu/sukurori don samun heatsink ɗin da aka gama.